Installation and usage of the machine:

(1) Installation of the machine

This machine is used before to be fixed on the anchor bolt, before installation should be according to the position shown lay the concrete foundation, do to be solid foundation, the machine adjustment to the horizontal position and fasten. After that the test run is allowed.

(2) Preparation

A. The hand turns the big belt wheel, the observation gear meshing is correct.

B. Check the parts of the fastening and loosening of the screw, check that the cover is reliable, each part whether obstacles

C. Circuit, motor must be in accordance with the provisions of the wiring, the bottom line contact to be strong

D. Must be in accordance with the lubrication of the machine

E. Empty test, found to have abnormal noise should stop immediately, check the reason and timely repair.

(3) Note in the use of machinery

A. After the machine starts, it is time to check whether the inertia wheel is correct, and it is not correct to use the machine.

B. Batch cutting, the use of the baffle positioning for continuous feeding.

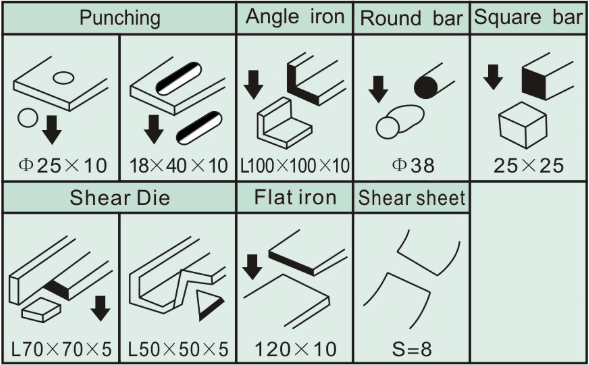

1. A movable blade fixing cut shear angle steel, round steel, Fang Gang.

2. On the lower edge, shear plate, flat steel.

3. Special angle punch and punch bottom shear angle knife shaped (see photo), punch and die can punch.

4. All kinds of knife edge and the punch cannot be mixed or work at the same time.

Special angle shearing diagrams

D. In a movable blade and a fixed blade between the shear angle, through the height adjusting rack disk can solve angle pot incision horseshoe. .

E. With the upper edge and the lower edge cutting, with the top wire to board flat on top and then cut, otherwise it will soon hit a knife

F. The gap between each blade and punch

1. On the blade, knife edge wear or after repair, the gap on both sides should be banished the whole uniform, adjust the gap to cut 3% thick plate.

2. Special angle punch and special angle iron bottom cutter is used, the gap should be adjusted to the shear angle thickness of 1/10.

3. In order to use the screw to adjust the die and punch the concentric position.

4. Punching hole, should will unload slot die, the Kong Moan on the die seat and fixed by screws, then the die fixed seat on the body, to be uniformly punch and die gap around the adjustment can be die cut (sheet thickness greater than 6 must positive heterotypic angle at the end of a knife unloading

G. To change the blade or the blade for the other side, the fixed blade and the movable blade can be replaced or replaced by the pad and the pad. When installing, blade is movably installed after the installation of the fixed blade. After mounting pad block and a pressing iron and tighten the bolts can be (to sharpen the knife blade, when install the pad please pad on the thickness of the gasket). When the blade is changed, the frame is changed to the surface of the material plate.