Machine lubrication and maintenance:

(1) maintenance of machine:

A, the machine is installed in place, should be the first wipe clean, and painted with a new lubricant, until the machine is fully lubricated, square

Can be officially opened.

B, the machine is in operation, should pay attention to the heating sleeve, bearing and motor temperature is too high, should stop using.

C, should be promptly cleaned up all the work of the tool and tool around the debris.

D, at the end of each shift, the machine must be clean, oil, to rust, long time should not remove the motor

Next, store in a dry place.

(2) lubrication of machine:

Good lubrication and correct oil, can ensure the normal operation of the machine, and can prolong its service life, so must pay attention to the lubrication of the machine. This machine all the oil cup are required to refuel, please use the lithium or calcium base lubricating oil.

A, the machine should be in accordance with the lubrication of each class 3 times, quantitative injection of qualified lubricating oil (grease).

B, lubricating oil should be stored in a closed container, often kept clean.

C, the machine is often unused, must be in the sliding rail at the lubrication oil (grease).

Installation and usage of the machine:

(1) The installation of a machine

Before using the machine to be fixed on the anchor bolt ruthenium, before installation should be according to the position shown lay the concrete foundation, do to be solid foundation, the machine is adjusted to the horizontal position and fasten: after before the test run. (shown below)

(2) Preparation for use

A.The hand turns the big belt wheel (or the flywheel), observe whether the gear meshing is correct.

B.Check the fastening parts, and the loosening of the screws tightened, check that the cover is reliable and there is no obstacle.

C.Electric circuit, motor must be in accordance with the provisions of the wiring, wire contact to be strong.

D.The lubrication of the machine must be in accordance with the lubrication requirements

E.For trial test, when found to have abnormal noise should stop immediately, check the cause and time to repair.

(3) Note in the use of machinery

A.After the machine starts, check whether the flywheel is correct, the use of the machine should be banned if it is not in the correct position.

B.Batch cutting, the use of the baffle positioning for continuous feeding.

C.

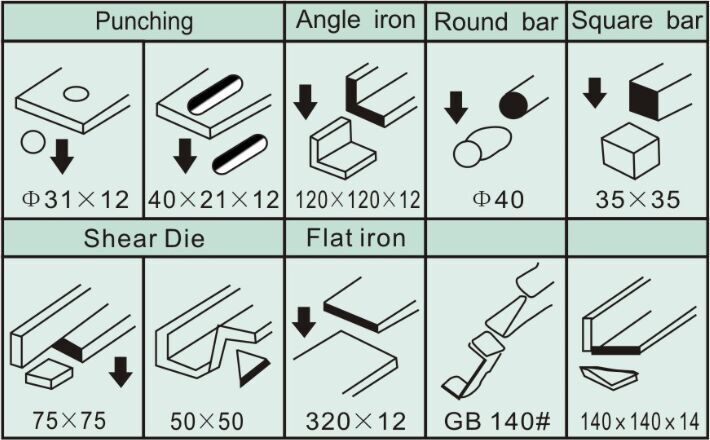

1.A movable blade, fixed blade angle steel, round steel shear.

2.The last, the knife edge shear plate, flat and diameter less than 11 mm round.

3.The various knife and punch cannot be mixed or work at the same time.

D.Between the moving cutter plate and fixed cutter plate shear angle (round), through the height adjusting rack disk can solve the angle steel, round steel) at the incision of the horseshoe shaped.

E.After repairing the upper and lower knives, with the top wire to board flat on top and then cut, otherwise it will damage very quickly on the edge.

F.the blade clearance, punch

1.On the blade, knife edge wear or after repair, the gap on both sides of the surface should be adjusted uniformly, adjust the gap to cut 3% thick plate.

2.The special angle and angle shaped punch bottom cutter is used, the gap should be adjusted to the shear angle thickness of 1/10.

In order to use the screw to adjust the die and punch the concentric position.

Punching hole should be unloaded slot die, - the Kong Moan on the die seat and fixed by screws, then the die base is fixed on the machine body, punch and die gap around the uniform adjustment can be blanking.